Service and Maintenance of Aerco Benchmark Boilers

Safety Order

Safety Order: Service and Maintenance of Aerco Benchmark Boilers

July 28, 2016

Reference Number:

SO-GA 2016-01

This safety order is issued pursuant to section 31 of the Safety Standards Act. A person affected by this safety order may appeal this order in writing to the Safety Standards Appeal Board within 30 days. The appeal process is set out on the Safety Standards Appeal Board website.

Failure to comply with a safety order is an offence under section 72 of the Safety Standards Act.

Part 1: Details of Regulated Work or Regulated Product

This safety order is being issued in relation to (circle or highlight one):

| Regulated Work – General | Regulated Products – General |

| Regulated Work – Specific Class | Regulated Product – Specific Class |

| Specific Regulated Work | Specific Regulated Product |

Part 2: Requirement(s) Of This Safety Order

The following Gas Boilers manufactured by AERCO International Inc. are affected:

AERCO Benchmark (BMK) Gas Fired Hot Water Boilers series models 1.5LN, 2.0LN, 3.0LN discontinued in 2012-2013

Owners of commercial or industrial buildings that contain these identified boilers must ensure:

- The boiler(s) must be updated by an individual with the appropriate gas Certificate of Qualification operating under a licensed gas contractor to increase the blower purge setting to ensure boiler (combustion chamber) and flue passages (connected venting) are completely purged 4 times prior to an ignition trial. Actions as detailed in the Aerco Technical Service Bulletin TSB-2016-04 must be followed.

- The boiler(s) is inspected at least annually by an individual with the appropriate gas Certificate of Qualification operating under a licensed gas contractor to verify:

- the correct installation and functioning of the current ignitor assembly provided by the manufacturer as set out below; and

- that the boiler is generally in safe operating condition.

- Any servicing or repairs required for the continued safe operation of the boiler(s) as identified by the inspecting gasfitter must be carried out in time to ensure that no potentially hazardous conditions are created or allowed to persist.

- Accurate records of any servicing or repairs shall be maintained on site and supplied to a Provincial Safety Manager or area Safety Officer upon request.

Note: This Safety Order applies only to Legacy models that were discontinued in 2012 -2013 not current models of Aerco Benchmark Boilers

Part 3: Details of Issue (If Applicable)

This safety order is being issued based on the following:

BC Safety Authority has been informed of seven ignition related incidents since 2011 involving Legacy AERCO Benchmark 1.5, 2.0 or 3.0 boilers in BC. These incidents were classified as “hard light-offs” or “delayed ignitions” and were described as a loud bang or pop during operation or start-up. All reported incidents resulted in damage to the connected venting system. BC Safety Authority has not received any reports of injuries.

In one recent incident the boiler had continued to function normally, while the venting system had become damaged and disconnected allowing products of combustion to vent into the building. Although the manufacturer noted that the installation -did not conformed to their recommended practices, this potential condition presents - safety hazard.

AERCO boilers require the blower to spin-down from its pre-purge speed to ignition speed for smooth light-off with the proper air/fuel ratio delivered to the premix burner. When an ignition trial occurs with high excess air due to excess blower speed, the boiler may fault on Flame Loss During Ignition (FLDI or may possibly result in a loud light-off with or without FLDI fault.

The mandatory requirements detailed in part 2 of this safety order are the corrective actions identified in the related incident investigations that will greatly reduce the likelihood of similar events. Incidents involving this type of product are required to be reported in accordance with the Safety Standards Act. If you discover any damage to your boiler or its venting system, or if you have experienced ignition system events with your product in the past, please email BC Safety Authority at stakeholder.engagement@safetyauthority.ca

IGNITER-INJECTOR Information

All Benchmark Boiler models, with the exception of model BMK 6000, use igniter-injector (Kit P/N 58023). Inspect and validate as per the maintenance schedule, replacement is required at least every 24 months of operation. Replacement may be required sooner if there is evidence of substantial erosion or carbon build-up.

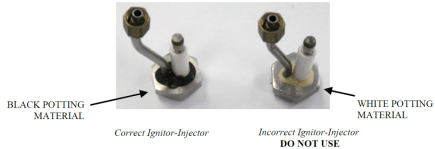

Make sure to use igniter-injectors with black potting material around the ceramic insulator. Do not install an older igniter-injector with white potting material.

Part 4: Details of Ordering Safety Manager or Safety Officer – Please Read Following Page

I certify that I am authorized to issue this safety order in accordance with section 15 (d) of the Safety Standards Act or that I have been delegated this power under section 15 (g) of the Safety Standards Act.

Brad Wyatt

Date: July 29, 2016

Provincial Safety Manager, Gas Technical Programs

References:

Safety Orders

31

- To prevent, avoid or reduce risk of personal injury or damage to property, a provincial safety manager may, in writing, issue a safety order.

- A safety order may be issued to any person in relation to any of the following:

- regulated work or regulated products generally;

- a specific class of regulated product or regulated work;

- a specific regulated product or regulated work.

- For certainty, a safety order issued under this section may apply to

- regulated work that meets the requirements under this Act,

- regulated work that previously met the requirements under this Act or a former Act but does not meet the current requirements under this Act,

- regulated products that meet the requirements under this Act, or

- regulated products that previously met the requirements under this Act or a former Act but do not meet the current requirements under this Act, including a regulated product that bears a certification mark.

- A safety order may specify any requirement that is intended to prevent, avoid or reduce the risk of personal injury or damage to property and may include any of the following orders:

- that an existing regulated work or regulated product must be made safe in compliance with the safety order;

- that a regulated product must be

- disconnected from a power source,

- uninstalled, or

- modified before continued use;

- that a regulated product must be operated, installed, manufactured or disposed of only as specified or that a regulated product must not be moved;

- that current or future regulated work or a regulated product must conform to the terms or conditions of the order;

- that a person take or refrain from taking any action that a safety manager considers necessary to prevent, avoid or reduce a risk of personal injury to persons or damage to property;

- that the manufacturer make reasonable efforts to recall the regulated product.

- The provincial safety manager must give written notice of the safety order to the following persons:

- the manufacturer of the regulated product;

- an owner of the regulated product if the identity of the owner is known to the provincial safety manager;

- the person in charge of the regulated work.

- The notice must state the reasons for the decision and that the person has the right to appeal the decision to the appeal board.

- Despite section 54, a safety order may not be stayed during an appeal.